RuScan

All of the medium or large capacity (with producing of 5 or more cubic meters of lumber per month) sawmills of the Russian Federation can’t allow themselves to sort such a big amount of produced lumber by hand due to economical or logistical reasons. As a result, the growth of demand in mechanical board sorting lines started about 15-20 years ago and continues today. The used equipment and morally and technologically out-of-date equipment is generally supplied.

Lumber quality control, optimization and end-cutting on the lines manufactured in the 90-s or in the beginning of 2000 are provided by 1 or several operators. Such a solution is not effective under conditions of growing competition in the lumber market, the production quality prevails. Lumber overload in the market causes inflated requirements of clients, price-cutting on a low-quality product. The product quality and, finally, its price are determined at dry sorting. Dependence on human factors is inappropriate. Mistakes made by operators reduce the profit of the whole mill. Important is every per cent, every part of per cent of yield. Automatic lumber scanners are used very often for solutions to this task. Thanks to this equipment have achieved considerable progress in sorting quality terms and in cross-cutting optimization in price. Consequently have increased the demands of clients.

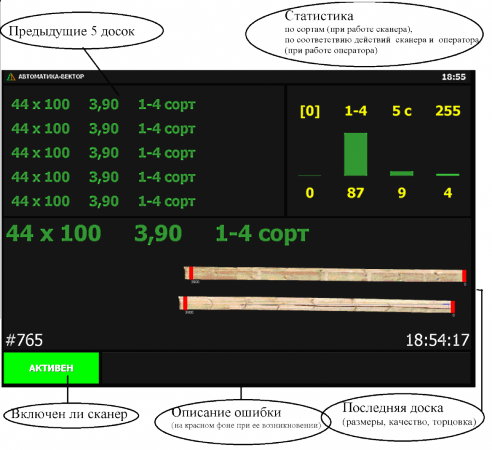

“RuScan” of “AVTOMATIKA-VEKTOR” – all-in-one system functions as lumber scanner, searching and measuring device of the geometry of defects, the sort used, species of wood determination, crosscutting optimization. The scanner has been successfully operating for a very long time in different regions of the country from Karelia to Eastern Siberia, were sorted millions of cubic meters of lumber were supplied to different markets with different kinds of specific requirements. In addition to this, this scanner is able to collaborate with the program-controlled crosscutting mechanisms and

pocket ordering by using general parameters and settings systems. Both of these programs have advanced reporting systems based on MS SQL, which is very convenient for analytics and export to other accounting systems. Clients also appreciated the convenience of reporting viewing by using the usual browser.

Advantages

- The construction was designed by using solutions and components, which allow operating equipment for many years, without repairing or modernizing.

- The most advanced searching and analysis technologies

- Detailed examination of the edge and face of the board on from both sides simultaneously. At the same time, the board is photographed from each side under four different light sources, simulating the rotation of the board when viewed. As a result, each board is photographed 16 times + 2 times from the edge. This is very important, especially by analyzing splits, steps and breakouts.

- End-to-end integration with other accounting and optimization software designed by “AVTOMATIKA-VEKTOR”.

- On-line technical support, intensive training of operating staff.

Technical Capabilities

The system detects geometric and visible defects. Geometric defects are defects of machining: wane, chipping, breaking, twist, bow, a crook. Visible defects detected by this system are rot, blue stain, knots, splits, bark, pitch pockets. Defect detection is performed on the basis of GOST 2140-81 “Visible defects of wood, classification, terms and definitions, methods of measurement.” Sorting and trimming are based on GOST 26002-83 “Coniferous sawn timber of Northern grading supplied for export”, with the possibility to set all parameters. RuSkan software has a clear and intuitive interface, comfortable and flexible configurations, which greatly facilitates personnel training and work with it. The introduction of an automatic scanner on the sorting line is destined to increase the productivity of the line, to ensure the growth of the value of finished products due to optimized decisions, to reduce the influence of the human factor, to provide a more stable product quality.

Visible defects

Knots: the following characteristics can be defined

- Type (displacements, connections, rotten)

- Location

- Size (ellipse – by the small diameter, by the edge – if it crosses the edge)

- Number (per 1 m of the board, on the whole length)

- Pass-through knot or not

Splits (type: a layer’s split, the edge’s split, penetrating / not penetrating, penetration in the butt end ).

Defects of structure (bark ringed knot, pitch pockets). Their dimensions (length, width), number, position (at the edge or on the layer) influences the choice of quality.

Fungal lesions (rottenness, blue stain) The choice of the sort is done according to the type of lesion, size of the segments relative to the length and width of the board, the percentage of the total area of lesions in regard to the layer of boards, going to the butt end, penetrating character (the transition from one layer to another).

Characteristics

- Board dimensions, precision: 10/1/0, 2 mm

- Detection and measurement wane

- Detection of defects on the face and on the edges of boards (according to the technical requirements of GOST 26002-83 and GOST 24454-80.):

- Knots: not adnate sound, decayed, rotten

- Holes of the fallen not adnate knots,

- Fungus heartwood spots and stripes

- Sapwood rot: hard/soft

- Heartwood rot: brown fissured / particoloured solid

- External soft rot

- Wormholes, pitch pockets

- Splits: face, edge, end

- Warp: bow, crook, and twist (on the edge or on the face).

Sorting accuracy of dry sawn timber of spruce and pine is not worse than 90%

Set Up

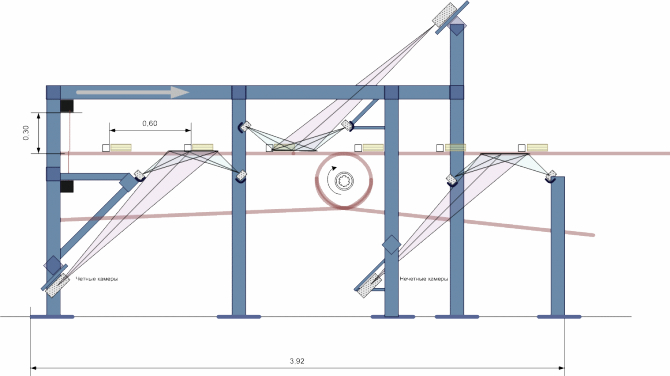

To detect defects the system uses two or three ramps with cameras and pin spots. Cameras can be on top of the conveyor as well as on both sides. It permits to go without the turn of the board and significantly reduce the length of the conveyor required to install the scanner.

To measure the thickness and wane the boards use high-speed laser sensors located in 30 or 15 cm along the board. They transfer information to the host computer via a digital network without loss of accuracy.