Accounting for round wood by weight method

General information

- Greenwood volume is up to 4 million m3 per year

- Greenwood: birch, aspen, spruce, pine.

- Delivery method: by lots using automobile transport separately by species

- Type of transport: log trucks, short log trucks with trailer (tractor-trailer) trucks. The maximum tractor-trailer length is 21 m, the maximum gross weight is 60 tons.

- The delivery schedule is non-stop, a non-uniform time during the day.

- The list of documents based on which the system is created:

- OST (Industrial Standard) 13-59-82.Round wood. The weight method for determining the volume and quality rating.

- TU (Technical Specifications) 13-2-8-96 Birch veneer logs, delivered to Finland. Specifications

- MVI (Measurement procedure)13-2-5-01 “Round wood delivered to Finland. The procedure of volume and selective mid-coefficient density measurements, quality control”

System requirements

General requirements

- Automatic control of reception station’s equipment

- Calculation of the volume of each lot of greenwood

- Accuracy of the lot volume calculation according to the OST 13-59-82 ( section 4)

- Database for greenwood, generation of reports

- Adjustment of the correction coefficients based on the results of random measurements

Equipment requirements

- Platform truck scale:

- Electronic strain gauge balance

- The weighing capacity range is 60 tons, with limits of error of + -1.5 % of the upper weighting limit (GOST 21524-76 )

- The size of the weighing platform is 22×3 m

- The intensity of weighing is up to 200 vehicles per day

- Operating conditions of scale platform : -45 – +45 C

- Automated line of greenwood acceptance

- Stacker, rolling capacity of 60m3, single-piece feeding

- Chain log conveyor with metal crossbars and relief shelf. Box storage capacity is up to 8 m3. The conveyor speed is adjusted from 30 to 150 m / minute. Capacity by time is from 20 to 120 m3/hr

- Log scanner VEKTOR 3D, database server, console, electric equipment.

The operator’s room is standard (BO88) with electric heating.

- Lighting equipment of traffic control (traffic light )

- Set of photo and video recording equipment.

- set of sensors controlling the perimeter of the weighing platform

- Equipment quantity and position must provide the registration and control of weighting the vehicle while driving through the scales in the forward and reverse directions.:

- Equipment installed in the control room. Control cabinet with electric equipment

- Personal computer with special software

Software

- The operating system is Windows XP SP2, database format is MS SQL Server, Access to the reports via WWW- interface

- Gathering data from system devices and issuing control signals in real-time

- Correction factors of pile mass transfer in the volume must be customizable:

- Density coefficient.

- Correction factor that takes into account the influence of external factors, such as dirt, snow and ice.

- Automatic data input about the lot: vehicle identification number, gross weight, empty weight, the attachment of pictures with the state of the log’s lot.

- Report of the lot shall contain the following information:

- state registration number of the vehicle

- supplier information, contract number

- shipping document’s information: species, length, volume as measured by the sender

- date/time of gross weight measuring

- gross weight

- photos of logs from various angles (up to 6 pcs. )

- date/time of empty weight measurement ( unloaded vehicle )

- empty weight

- the calculated weight of the of logs lot;

- the volume of logs lot

- coefficient of density defining the volume of the party,

- correction for external factors such as dirt, snow and ice.

- text remarks of acceptance operator

- name of operators accepting the lots of the party

- report for the period by suppliers

- report for the period by control lots

Function

The volume of timber in the lot is determined by the result of measurement of weight using the coefficient of conversion of weight in the volume at a rate of mass transfer in the volume, the value of which is set by samples (OST 13-59-82 clause 1.1 ).

The volume is calculated according to the formula:

Q = k * M, where

Q – the volume of timber in the lot, m3

k – coefficient of weight transfer in the timber volume

M – the weight of the timber’s lot, ton

The weight of the timber lot is calculated as the difference between the gross weight and the empty weight.

At the first stage, the conversion factor is determined for each lot of timber, according to the requirements of OST 13-59-82 clause 3.3. The operating system uses a constant conversion factor with the periodic control of its stability at least once a month.

Description of acceptance procedure

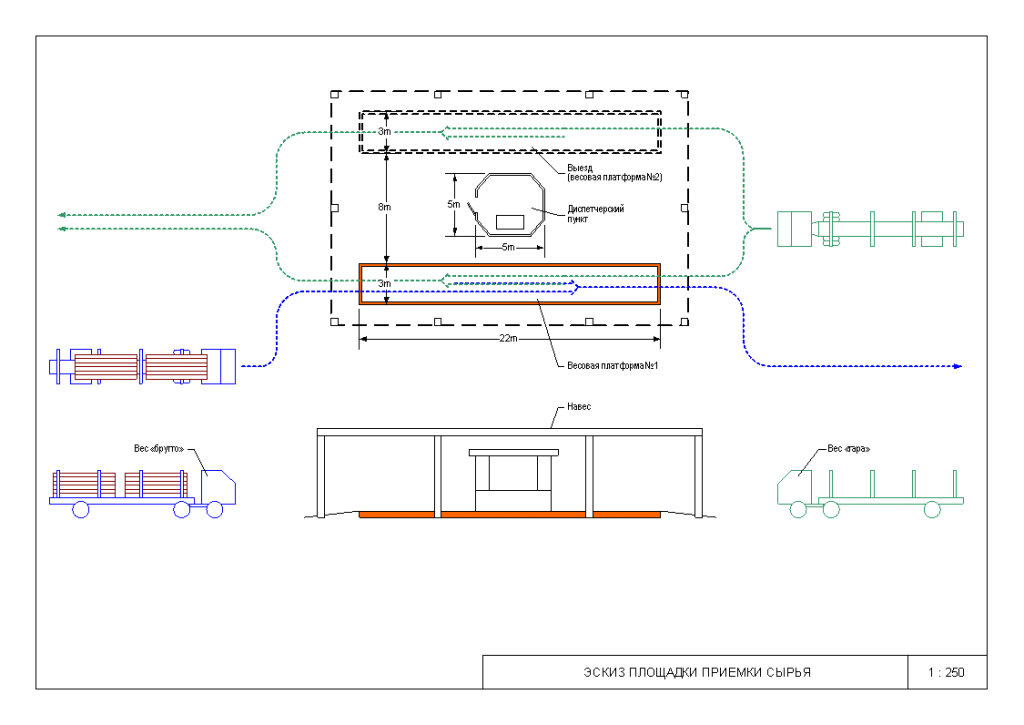

At the first stage of commissioning, we think that it’s necessary to organize the acceptance of the timber using a weighing platform, with the possibility to provide connectivity to the automatic acceptance system by extra weight settings.

Acceptance point consists of weighing platform and cabin of acceptance’s operator. The weighing platform is equipped with traffic lights to organize traffic in both directions, perimeter controlling sensors, registering cameras, lighting. For protection from the weather, it’s necessary to build a shedding on the weighing platform and operator’s cabin. The operator’s cabin is equipped with a control cabinet with electrical equipment and a personal computer. The process of acceptance of each lot is realized in two stages. At the first stage, the system determines the weight of the loaded vehicle, the second stage is the determination of the weight of the unloaded vehicle.

According to the enable signal of traffic light the loaded vehicle drives on the scale and stops at the determined place of the platform. The system determines the gross weight of the vehicle and transfers data to a PC. The camera records the registration number of the vehicle, which is recognized by the program, information about the supplier is recorded from the database to the information about the lot. The operator of acceptance files in a special form on the PC the data of shipping document. Assistant of the operator makes visual quality control of log’s lot and fixes the look of the lot with a digital camera equipped with a wireless network interface. Once all the preliminary information about the lot is formed and recorded, the system sends the signal to unload the vehicle. The next vehicle drives on the weighing platform. The duration of acceptance of one lot is not more than 5 minutes.

Unloaded vehicles are returned to the weighing platform. The operator switches the mode of the system to determine the empty weight. The system switches to control the movement on the weighing platform in the opposite direction. According to the enable signal of the traffic light, the vehicle drives on the weighing platform. The system determines the empty weight, identifies the vehicle number, compares it with the lot, and forms the final information on the lot, which is stored in the database. For vehicles the empty weight of which has been weighed several times and had approximately the same value it is possible to set a mode when vehicles are not weighed again, the empty weight for the lot is taken as the average of the last values for this vehicle saved in a database. The appropriate note is made in the report by the lot.

Control of conversion factor stability

To ensure the required accuracy in determining the volume it’s necessary to control periodically the conversion factor. In the normative documents, there are two possibilities for controlling the conversion factor.

According to the requirements of OST 13-59-82 p.3.4.4: when using a constant factor or if you change the species composition, time and place of logging, storage conditions, it is necessary to control its stability at least once a month. Control of conversion factor stability is carried out on a sample of 50 m3 of the lot in accordance with clause 3.3.4. (random sampling ) and clause 3.3.5. (coefficient calculation formula as the ratio of volume to the weight) and comparison with the current conversion factor. If its value differs more than 3.3 %, the system chooses the additional sample of 50 m3, calculates a new control value for the conversion factor for the total volume of 100 m3 and compares it with the current value. If the difference once again exceeds 3.3%, it is necessary to define a new permanent conversion factor and its application with the periodic control.

Another way to use and control conversion factor is stated in the methodology Measurement procedure13-2-5-01 clause 5.3. It is named the coefficient of density. This procedure reaches the logs delivered to Finland. According to this the sampling density coefficient is set by random measurements. The choice of the pile in the selection is carried out without separation by suppliers with taking into account the following conditions:

- the volume of timber in the sample group must be at least 6 % of the timber delivered under the contract,

- selection of the piles should be random,

- selection doesn’t include log piles that are not found suitable for acceptance according to the results of the visual quality control clause 5.1.

Measured pile parameters:

- weight of the pile under clause 5.2

- the volume of logs in a pile by one of the single-piece methods according to the methodology Measurement procedure 13-2-1-01, or through the automated line of single-piece acceptance of raw wood by volume.

The random density coefficient is calculated by the formula K = M / Vв5

where:

K – random density coefficient, t/m3

MB5 – the weight of the last five piles in the sample under this contract, t,

VB5 – the total volume of logs in the last five piles in the sample under this contract, m.

To measure the first lots under the new contract the sample includes the first five piles of timber. Further, the choice of piles in the sample is random according to the following rules. The new value of the random density coefficient is put in at 00 a.m. following the date of measurement. This value is applied to all piles to be measured in the period until the next adjustment of density coefficient after random choice of the pile.