Log scanners "Vektor"

Hystory

The prototypes of electronic devices that use the principle of scanning by infrared rays for automatic calculating of the cubic capacity and measuring of the log diameter were developed by the Laboratory of the industrial log depot of SevNIIP in 1989 (Arkhangelsk). The first pre-production model, the prototype of modern infrared scanners, was installed in 1990 at the timber industry enterprise Mitino( the Vologda region) as a part of the automatic log sorting control system LT-192I. The log measuring device was successfully tested and approved by the State Commission in series production. All these years device was modernized, the algorithms and element base were improved. Now comes the fifth generation of these measuring devices. They are used at different technological stages of sawing from sorting of sawn material to the control system of log positioning on the band log frame. System of input registration of raw material began to be installed more than 15 years ago and currently already work at hundreds of sawmills, plywood and match factories. The basis of the recording system is a simple, reliable and inexpensive log measuring device in one plane VECTOR 2010E. Modern requirements for measurements provide both high accuracy and repeatability of measurements and advanced functionality: measurement of a complete log profile, ovality and crookedness. Designed by our specialists the log scanner VECTOR 3DE meets these requirements and has already gained significant market share in Russia, Lithuania, Latvia, Estonia and Germany thanks to its functional qualities, reliability and competitive prices.

Options

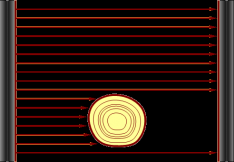

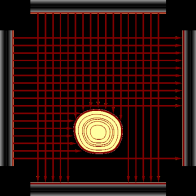

Scanning of log profile in one or two planes, as well as a full surface scan of the logs (to obtain 3D profile), moving on a conveyor. mathematical profile processing in order to eliminate confounding factors, (hanging bark, stirring elements of the conveyor) and transfer of processed values – the geometric log parameters(the diameter, length, volume, crookedness, ovality, falloff, buttress) in the upper-level systems.

Applications

The log scanners VECTOR are used at enterprises of timber industry complex as a device for measuring the geometrical log parameters in the round timber sorting lines. Large sectors of use of such scanners are the automation of round timber сontrol system, the organization of round timber, input control of round timber, measurement of bricks, semi bricks, half-timber, it can be used as a measuring device in automated cutting lines at sawmills. At the plywood mills –veneer materials control when feeding in the peeling floor and at the crosscut of technical raw materials.

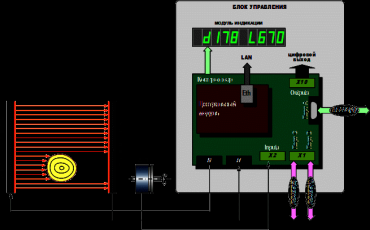

Main technical data (depend on modification)

Log’s diameter, mm 0 … 700 … 800

Accuracy of diameter measurements, mm ± 2,0, ± 1,0

Log’s length, m 0,50 … 9,99

Length measuring accuracy, mm ± 30

Frequency, c-¹, minimum 50 … 150 … 250

Supply voltage: 24 VDC, 220 VAC

Communications

The scanner is equipped with serial ports RS232, RS485 and Ethernet port.

Exception of bark

For each log, the recording system automatically calculates the thickness of the bark. The algorithm of calculation is determined by wood species and depends directly on the log’s diameter. Basic configuration coefficients of bark exception configured during setup and in the future can be adjusted by the responsible person with a special menu, the entrance to which is available via password. Thus achieve maximum reliability of the information in the measurement of logs with bark.

Set up

Set up of the log measuring device is made by using a terminal or the wizard Scanner Setup.

Universal scanner settings by means of controlled parameters allow to adapt it to the particularities of measurements in different types of conveyors.

Measuring mode

The basis of high measurement accuracy is a lot of measurements on all lengths of the log as it passes through the measuring cross-section (such as 3D scanning profile is based on hundreds of thousands of points). Further multipass profile processing by special algorithms analyzes the information and screenings of confounding factors: the bark on the log may be damaged, knots, chips, etc. The diameter of the front and back end is defined with a small indentation (the value is set in user settings).

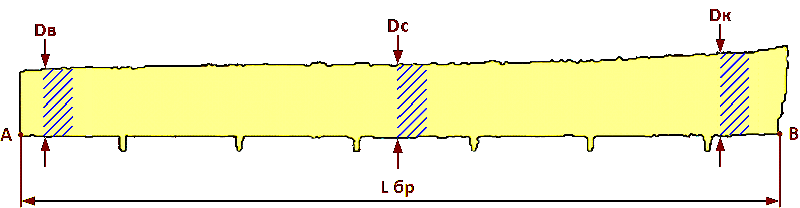

The correct length definition is also produced by a special algorithm – at the log profile, there are the points at which the edge of the profile makes a sharp step (points A and B in Figure 1). The log length by definition – is the shortest distance between the ends, which corresponds to the distance between points A and B. Determination of the log volume, due to the large number of the obtained values can be calculated practically by any method recommended by Russian and international standards, (according to the tables of GOST-STANDARD 2708-75, using the top diameter method, using the middle diameter method(«Huber»), using the end-cut method, etc.). Calculation of volumes on various standards and methods, the accumulation of databases, generation of report documents lies on the software of the upper level, which is installed on the standard personal computers or specialized controllers of the process control.

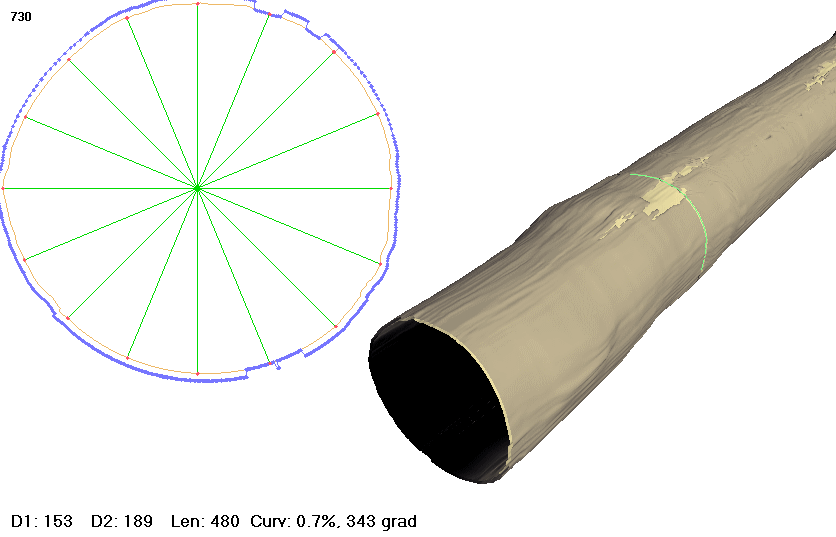

VEKTOR 3D – log measuring device.

Function

Log geometric parameters measuring device VEKTOR 3D is designed to work as an automatic means of log measurements in automatic sorting lines of round timber, sawing optimization systems and log recording systems. VEKTOR 3D consists of a system of cameras and laser markers, placed at an angle to each other. On the log, surface lasers create a line visible on the frames of the video cameras and form a complete outline of the log cross-section. The signal from the camera goes to the computer capture card, is converted into digital form and processed by special software. The result of the log cross-section contour processing is the determination of its size and shape. Thus, on the log surface can be found bouges (knots, knogs) and cavities (hollows). Other log parameters (volume, crookedness, rise, etc.) are calculated on the basis of log diameters and length measurements.

Advantages

3D realistic measurements; Installation at all types of conveyors, doesn’t require interruption of the safe to operate, resistant to climatic changes.

Main function

Measurement and transmission of information about the log geometrical parameters in real-time:

- Front end diameter;

- Middle-section diameter;

- Back-end diameter.

VECTOR 3D Bark. Automatic compensation of the bark

Further development of 3D log scanner is on the way to improve the measurement reliability, particularly logs with bark. Measurement of logs with a partially peeled-off bark is a problem for all types of scanners. Our engineers and programmers have developed a method to measure such logs. Use of the information about the brightness of the reflected laser beam helps to identify areas where there is no bark. Specially selected laser and cameras, as well as the software filter, increase the probability of identifying such sites to 90%. Compensation for the thickness of bark to such sites does not apply, and thereafter the accuracy of log diameter measurement remains at a high level. In further cutting the additional percentage of useful yield will be received.